Ever wondered if your trusty lead-acid battery setup is living its best life? Are you squeezing every last drop of power out of it, or are you unknowingly shortening its lifespan? This is a question that many grapple with, especially when venturing into off-grid living, powering electric vehicles, or relying on backup power systems.

The frustration of dealing with a prematurely failing battery is something many people can relate to. Imagine planning a camping trip only to find your battery unable to power your essential devices. Or perhaps you're investing in a solar panel system, only to discover that the lead-acid batteries are degrading faster than expected, impacting your overall energy independence. These scenarios highlight the critical need to ensure your lead-acid batteries are properly managed and maintained for optimal performance and longevity.

The answer to whether you need a Battery Management System (BMS) for a lead-acid battery isn't a simple yes or no. It depends on your application, budget, and the level of protection you desire. For a simple, single-battery setup like a car battery, the vehicle's charging system often suffices. However, in more complex systems – such as those powering electric vehicles, solar setups, or backup power systems – a BMS is highly recommended, and often crucial, to ensure optimal performance, safety, and lifespan of your lead-acid batteries.

In essence, a BMS acts as a guardian for your lead-acid batteries, monitoring voltage, current, temperature, and overall health. It prevents overcharging and deep discharging, both of which can significantly reduce battery life. While not always necessary for simple applications, a BMS is a worthwhile investment for complex systems where battery health and longevity are paramount. Let's dive into the specifics of how a BMS can benefit your lead-acid battery setup.

Do I Need a BMS? A Personal Anecdote

I remember when I first started experimenting with off-grid solar power. I was so excited to power my shed with the sun's energy. I bought a couple of lead-acid batteries, hooked them up, and thought I was good to go. I didn't bother with a BMS, figuring the charge controller was enough. The first few months were great – lights, a small fan, all powered by the sun! But then, I started noticing a decline in battery performance. They wouldn't hold a charge as long, and the lights would dim much faster than before.

Eventually, one of the batteries completely died. Turns out, I was over-discharging them regularly, which severely shortened their lifespan. It was a costly lesson. I ended up replacing both batteries and, this time, invested in a proper BMS. The difference was night and day. The batteries lasted significantly longer, and I had peace of mind knowing they were protected from overcharging and deep discharging. That experience taught me that while a lead-acid battery can function without a BMS in simple applications, in more demanding setups, it's an absolute necessity for long-term reliability and cost-effectiveness. The BMS continuously monitors the state of the battery, balances the charge across multiple batteries in a bank, and provides essential data for optimizing energy usage. It's not just about preventing damage; it's about maximizing the return on your battery investment.

What is a Battery Management System (BMS)?

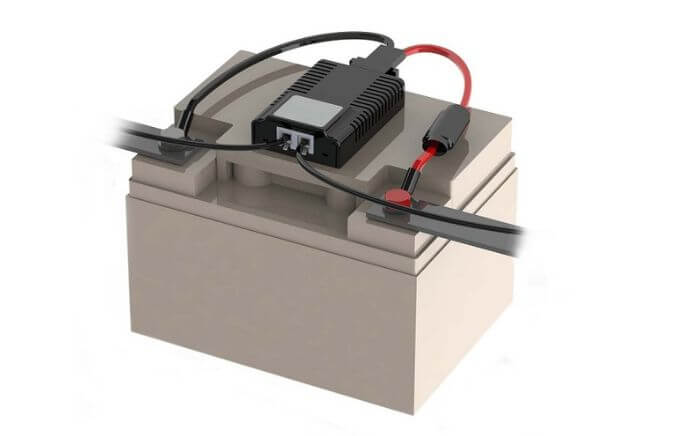

A Battery Management System (BMS) is essentially an electronic control system that manages rechargeable batteries, most often lithium-ion batteries (although versions exist for lead-acid batteries). Its primary functions include protecting the battery from operating outside its safe operating area, monitoring its state, calculating secondary data, reporting that data, and controlling the battery's environment. For lead-acid batteries, a BMS typically focuses on preventing overcharging and deep discharging, as these are the two biggest killers of these battery types. It monitors voltage, current, and temperature, and it can disconnect the battery from the load or charging source if it detects a problem.

Think of it like a bodyguard for your battery. The BMS ensures that the battery operates within its specified limits, extending its lifespan and preventing potential safety hazards. In more advanced systems, the BMS can also balance the charge across multiple batteries connected in series or parallel, ensuring that each battery is charged and discharged evenly. This is crucial for maximizing the overall capacity and lifespan of the battery bank. The BMS often communicates with other components in the system, such as the charge controller and inverter, to optimize energy flow and prevent damage to the batteries. In essence, the BMS is the brains of the operation, ensuring that your lead-acid batteries operate efficiently and safely.

History and Myths Surrounding BMS for Lead-Acid Batteries

Historically, Battery Management Systems were primarily associated with lithium-ion batteries, largely due to their sensitivity to overcharging and thermal runaway. Lead-acid batteries, being more robust, were often considered less critical in needing such sophisticated management. This led to a common myth that BMSs were unnecessary for lead-acid batteries. However, as lead-acid batteries found their way into more demanding applications like solar energy storage, electric vehicles, and high-performance backup systems, the limitations of relying solely on simple charge controllers became apparent.

Overcharging, deep discharging, and sulfation – all common issues with lead-acid batteries – could significantly reduce their lifespan and performance. This prompted the development and adoption of BMS specifically designed for lead-acid batteries. These systems, while simpler than their lithium-ion counterparts, offer crucial protection and optimization features that extend battery life and improve overall system efficiency. The myth that lead-acid batteries don't need BMS is slowly being dispelled as more users experience the benefits of proper battery management, particularly in demanding applications. The historical focus on lithium-ion batteries has somewhat overshadowed the value of BMS for lead-acid, but as technology advances and energy storage needs become more critical, the importance of proper management for all battery types is becoming increasingly clear.

The Hidden Secret of Extending Lead-Acid Battery Life

The hidden secret to significantly extending the lifespan of your lead-acid batteries lies in consistent and precise management of their charging and discharging cycles. While lead-acid batteries are known for their robustness and affordability, they are also susceptible to damage from overcharging, deep discharging, and sulfation. A well-implemented BMS addresses these issues head-on, preventing premature battery degradation and maximizing its usable life. It does this by closely monitoring voltage, current, and temperature, and adjusting the charging and discharging parameters accordingly.

For example, a BMS can prevent overcharging by cutting off the charging source once the battery reaches its optimal voltage level. Similarly, it can prevent deep discharging by disconnecting the load when the battery voltage drops below a certain threshold. Furthermore, some BMSs incorporate desulfation features, which can reverse the sulfation process that occurs when lead-acid batteries are left in a partially discharged state for extended periods. This hidden level of control and protection can translate into years of added life for your lead-acid batteries, saving you money and reducing the environmental impact of frequent battery replacements. The key is to view the BMS not just as a protective device, but as a proactive tool for optimizing battery performance and longevity.

Recommendations for Choosing a Lead-Acid Battery BMS

When selecting a Battery Management System for your lead-acid batteries, consider the following factors: your specific application, the size and configuration of your battery bank, and the level of protection you require. For simple, single-battery setups, a basic BMS that prevents overcharging and deep discharging might suffice. However, for more complex systems with multiple batteries connected in series or parallel, you'll want a BMS with advanced features like cell balancing and temperature monitoring.

Look for a BMS that is compatible with your battery type (e.g., flooded, AGM, gel) and voltage. Pay attention to the BMS's current rating, ensuring it can handle the maximum current draw of your load and the charging current of your charging source. Also, consider the BMS's communication capabilities. Some BMSs can communicate with other devices in your system, such as the charge controller and inverter, allowing for coordinated control and optimization. Finally, read reviews and compare prices from different manufacturers to find a BMS that offers the best value for your needs. Remember that investing in a quality BMS is an investment in the longevity and performance of your lead-acid batteries.

Understanding Key BMS Features for Lead-Acid Batteries

Delving deeper into the key features of a Battery Management System for lead-acid batteries, it's essential to understand how each feature contributes to overall battery health and performance. Overcharge protection is a fundamental function, preventing the battery voltage from exceeding safe limits, which can lead to gassing, electrolyte loss, and premature failure. Deep discharge protection safeguards against excessive depletion of the battery's energy reserves, which can cause irreversible damage to the plates and reduce its capacity. Temperature monitoring is crucial as extreme temperatures can significantly impact battery performance and lifespan. High temperatures accelerate corrosion and electrolyte degradation, while low temperatures reduce capacity and charging efficiency.

Cell balancing is particularly important in multi-battery systems, ensuring that each battery in the bank is charged and discharged equally, preventing imbalances that can lead to premature failure of individual batteries. State of Charge (SOC) and State of Health (SOH) estimation provide valuable insights into the battery's current capacity and overall condition, allowing you to proactively address potential issues before they escalate. Communication capabilities, such as CAN bus or Modbus, enable the BMS to interface with other system components, such as charge controllers, inverters, and monitoring systems, allowing for coordinated control and data logging. By understanding these key features, you can make a more informed decision when selecting a BMS for your lead-acid battery setup.

Tips for Maintaining Lead-Acid Batteries with a BMS

Even with a Battery Management System in place, proper maintenance is still crucial for maximizing the lifespan of your lead-acid batteries. Regularly inspect your batteries for signs of corrosion, swelling, or leakage. Clean the terminals with a wire brush and apply a corrosion-inhibiting spray to prevent future buildup. Ensure that the batteries are properly ventilated to prevent the accumulation of explosive gases during charging. Monitor the electrolyte level in flooded lead-acid batteries and add distilled water as needed to maintain the proper level.

Avoid deep discharging your batteries as much as possible, as this can significantly reduce their lifespan. If your BMS has the capability, configure it to disconnect the load before the battery voltage drops too low. Store your batteries in a cool, dry place when not in use. If you're storing them for an extended period, fully charge them before storage and periodically check the voltage to ensure they don't self-discharge too much. By following these simple tips, you can extend the life of your lead-acid batteries and get the most out of your BMS investment. Regular checks and proactive measures will ensure optimal performance and reliability.

Understanding Sulfation in Lead-Acid Batteries

Sulfation is a major culprit in the degradation of lead-acid batteries. It occurs when lead sulfate crystals form on the battery plates, hindering the electrochemical reactions necessary for charging and discharging. This process is accelerated when batteries are left in a partially discharged state for extended periods. The lead sulfate crystals gradually build up, reducing the battery's capacity and its ability to accept a charge. While sulfation is a natural process in lead-acid batteries, it can be mitigated through proper charging practices and the use of a BMS with desulfation capabilities.

Desulfation involves applying a specific charging profile that helps to break down the lead sulfate crystals and convert them back into active materials. Some BMSs incorporate desulfation algorithms that automatically perform this process periodically, helping to reverse the effects of sulfation and restore the battery's capacity. Preventing sulfation in the first place is also key. This can be achieved by ensuring that batteries are fully charged regularly and avoiding prolonged periods of partial discharge. By understanding the process of sulfation and taking steps to mitigate it, you can significantly extend the lifespan of your lead-acid batteries.

Fun Facts About Lead-Acid Batteries

Did you know that the lead-acid battery is one of the oldest rechargeable battery technologies, dating back to 1859? Invented by French physicist Gaston Planté, it was the first rechargeable battery and has been a workhorse of energy storage ever since. Despite being relatively heavy and bulky compared to newer battery technologies like lithium-ion, lead-acid batteries remain popular due to their low cost, reliability, and robustness. They are commonly used in automobiles, backup power systems, and off-grid solar installations.

Another fun fact is that lead-acid batteries are highly recyclable. In fact, they are one of the most recycled products in the world, with over 99% of battery components being recovered and reused. This makes them a more environmentally friendly option than many other battery types. Lead-acid batteries come in various forms, including flooded, AGM (Absorbent Glass Mat), and gel batteries, each with its own advantages and disadvantages. Flooded batteries are the most common and require regular maintenance, while AGM and gel batteries are sealed and maintenance-free. Despite their long history, lead-acid batteries continue to be an important part of our energy landscape, providing a reliable and affordable energy storage solution.

How to Choose the Right Size BMS for Your Lead-Acid Battery

Selecting the right size Battery Management System (BMS) for your lead-acid battery is crucial for ensuring optimal performance and protection. The most important factor to consider is the maximum current draw of your load. The BMS must be able to handle this current without overheating or failing. Check the specifications of your inverter, appliances, or other devices connected to the battery to determine the maximum current they will draw.

Also, consider the charging current of your charging source, such as a solar charge controller or AC charger. The BMS should be able to handle this current as well. Choose a BMS with a current rating that is at least 20% higher than the maximum current draw and charging current to provide a safety margin. Another factor to consider is the voltage of your battery bank. The BMS must be compatible with the voltage of your battery system. If you have multiple batteries connected in series, the BMS must be designed to handle the combined voltage. Finally, consider the number of batteries in your bank. Some BMSs are designed to handle multiple batteries connected in parallel, while others are not. By carefully considering these factors, you can choose a BMS that is properly sized for your lead-acid battery system.

What If I Don't Use a BMS with My Lead-Acid Battery?

The consequences of not using a Battery Management System (BMS) with your lead-acid battery can range from reduced battery lifespan to potential safety hazards. Without a BMS, your battery is more susceptible to overcharging, deep discharging, and sulfation, all of which can significantly shorten its lifespan. Overcharging can cause gassing, electrolyte loss, and corrosion, while deep discharging can damage the battery plates and reduce its capacity. Sulfation occurs when lead sulfate crystals form on the battery plates, hindering the electrochemical reactions necessary for charging and discharging.

In extreme cases, overcharging can lead to thermal runaway, which can cause the battery to overheat, vent explosive gases, and even catch fire. Without a BMS to monitor the battery's voltage, current, and temperature, you are essentially flying blind and relying on chance to prevent these issues. While some lead-acid battery systems can function without a BMS, particularly in simple applications with limited current draw and charging rates, the risk of damage and reduced lifespan is significantly higher. Investing in a BMS is a proactive way to protect your battery investment and ensure its long-term reliability. In short, skipping the BMS is a gamble with your battery's health and safety.

Listicle: Top Reasons to Use a BMS with Lead-Acid Batteries

Here's a quick list of the top reasons why you should consider using a Battery Management System (BMS) with your lead-acid batteries:

- Extends Battery Lifespan: Prevents overcharging, deep discharging, and sulfation, maximizing the usable life of your batteries.

- Improves Performance: Ensures optimal charging and discharging, leading to better battery performance and efficiency.

- Enhances Safety: Protects against thermal runaway, overvoltage, and other potential safety hazards.

- Reduces Maintenance: Automates battery management, reducing the need for manual monitoring and adjustments.

- Provides Data Logging: Tracks battery voltage, current, temperature, and other parameters, providing valuable insights into battery health.

- Optimizes Charging: Adjusts charging parameters based on battery condition, ensuring optimal charging efficiency.

- Balances Cells: Ensures that each battery in a multi-battery system is charged and discharged equally.

- Saves Money: Reduces the need for frequent battery replacements, saving you money in the long run.

- Peace of Mind: Provides peace of mind knowing that your batteries are protected and properly managed.

- Environmentally Friendly: Extends battery life and reduces the need for battery disposal, contributing to a more sustainable environment.

Question and Answer Section

Here are some frequently asked questions about Battery Management Systems for lead-acid batteries:

Q: Is a BMS absolutely necessary for all lead-acid battery setups?

A: Not necessarily. For very simple setups, like a single car battery charged by the vehicle's alternator, a BMS might not be essential. However, for more complex systems with multiple batteries or demanding applications, a BMS is highly recommended.

Q: Can I use a BMS designed for lithium-ion batteries with my lead-acid batteries?

A: No, you should not. Lithium-ion BMSs use different charging algorithms and voltage ranges than lead-acid batteries. Using the wrong BMS can damage your batteries and potentially create a safety hazard.

Q: How much does a BMS for lead-acid batteries cost?

A: The cost of a BMS can vary depending on its features and current rating. Basic BMSs can cost as little as $50, while more advanced models can cost several hundred dollars.

Q: Where can I buy a BMS for lead-acid batteries?

A: You can purchase BMSs from various online retailers, battery suppliers, and solar energy equipment providers. Be sure to research different brands and models to find one that meets your specific needs and budget.

Conclusion of do i need a battery management system for lead acid battery

Ultimately, deciding whether or not you need a Battery Management System for your lead-acid battery comes down to your specific requirements. For simple applications, the added cost and complexity may not be justified. However, for complex systems powering critical equipment or demanding applications, a BMS is a worthwhile investment. It will protect your batteries, extend their lifespan, and provide valuable data for optimizing energy usage. Consider the potential cost of replacing your batteries prematurely versus the cost of a BMS, and weigh the benefits accordingly. By making an informed decision, you can ensure that your lead-acid batteries operate efficiently and reliably for years to come.